As temperatures continue to climb, finding effective ways to beat the heat becomes a pressing concern for many individuals and families. While air conditioning can provide relief indoors, enjoying outdoor activities or even managing indoor spaces without AC can be challenging. This is where a homemade cooler comes into play, offering a practical and cost-effective solution to staying cool while also saving money. In this guide, we'll delve into the intricacies of creating your very own DIY cooler from items that might otherwise end up in the trash, helping you stay cool and environmentally conscious at the same time.

Before embarking on the journey of constructing a homemade cooler, it's crucial to grasp why such a project is not only beneficial but also necessary for many individuals. Commercial coolers, while effective, can often come with a hefty price tag, making them inaccessible to those on a tight budget. Additionally, the environmental impact of manufacturing and disposing of these coolers cannot be overlooked. By opting for a DIY approach, individuals have the opportunity to repurpose existing materials, thereby reducing waste and minimizing their carbon footprint. Moreover, DIY coolers offer a level of customization and creativity that commercial products may lack, allowing individuals to tailor their cooling solutions to their specific needs and preferences.

The beauty of creating a homemade cooler lies in its simplicity and reliance on readily available materials. By repurposing items that are commonly found around the house, you can transform seemingly ordinary objects into functional and efficient cooling devices. Here's a comprehensive list of materials typically used in DIY cooler projects:

Styrofoam boxes, often used for packaging perishable goods, and cardboard boxes, readily available from shipments or grocery purchases, serve as the foundational structure for the homemade cooler. Both materials offer insulation properties that help maintain low temperatures within the cooler.

To enhance the insulating capabilities of the cooler, insulating materials such as bubble wrap or foam sheets are used to line the interior walls of the box. These materials help trap cold air inside the cooler while preventing heat from infiltrating.

Reflective surfaces play a crucial role in minimizing heat absorption and retention within the cooler. Reflective tape or aluminum foil is applied to the interior walls of the box, effectively bouncing off incoming heat and maintaining cooler temperatures.

Duct tape or strong adhesive is used to secure various components of the cooler together and reinforce seams, ensuring durability and longevity.

A utility knife or scissors are essential tools for cutting and shaping materials during the construction process, allowing for precise customization of the cooler's components.

Accurate measurements are key to ensuring a snug fit and optimal insulation within the cooler. A ruler or measuring tape helps achieve consistency and precision throughout the construction process.

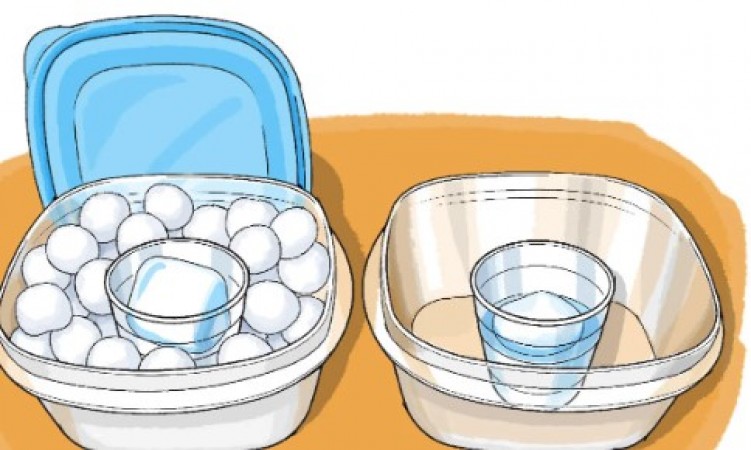

To provide the necessary cooling power, ice packs or frozen water bottles are placed inside the cooler to chill its contents. These reusable cooling agents offer a sustainable alternative to disposable ice packs.

For added insulation and temperature regulation, old towels or blankets can be used to line the exterior of the cooler or wrap around its contents. This additional layer helps further minimize heat transfer and maintain cold temperatures.

For outdoor use or situations where the cooler may be exposed to moisture, a waterproof sealant can be applied to seal any gaps or openings in the box, preventing water ingress and preserving the integrity of the insulation.

Now that you have gathered all the necessary materials, it's time to roll up your sleeves and embark on the journey of building your very own DIY cooler. Follow these step-by-step instructions to ensure a successful construction process:

If you've opted for a cardboard box, begin by reinforcing it with duct tape along the seams and edges to enhance its structural integrity. For styrofoam boxes, this step can be skipped as they typically provide sufficient durability on their own.

Next, line the interior walls of the box with insulating material such as bubble wrap or foam sheets. Cut the material to size using a utility knife or scissors, ensuring complete coverage of the walls and bottom of the box. This layer of insulation will help trap cold air inside the cooler and prevent heat from entering.

Apply a layer of reflective tape or aluminum foil to the interior walls of the box, ensuring that all surfaces are covered. The reflective surface will help deflect incoming heat and maintain cooler temperatures within the box, enhancing its overall efficiency.

If your box comes with a lid, it's essential to add insulation to this component as well. Repeat the process of lining the lid with insulating material and reflective surface, ensuring a tight seal when closed. This step prevents cold air from escaping through the top of the cooler, maximizing its cooling potential.

Inspect the box for any gaps or openings that may compromise its insulation capabilities. Use duct tape or waterproof sealant to seal these areas, ensuring an airtight seal that prevents warm air from entering and cold air from escaping.

Before putting your homemade cooler to use, it's essential to conduct a thorough test to ensure its effectiveness. Place ice packs or frozen water bottles inside the cooler and monitor the internal temperature over time. Make any necessary adjustments, such as adding additional insulation or sealing gaps, to optimize the cooler's performance.

With your homemade cooler successfully constructed and optimized for performance, it's time to reap the rewards of your efforts. Whether you're planning a picnic in the park, a day at the beach, or a backyard barbecue, your DIY cooler will keep your refreshments chilled and your spirits high. By harnessing the power of repurposed materials and ingenuity, you've not only saved money but also contributed to a more sustainable future. So, why spend a fortune on commercial coolers when you can create your own using items you already have? Embrace your creativity, reduce waste, and beat the heat with a homemade cooler that's as budget-friendly as it is effective!

This Honda sedan was once a customer's favorite, now it has become a big deal

Air bubbles not only inside the car but also outside, why do mechanics do this?

What is the difference between ORVM and Rear Mirror, which one is used for what?